Those 3 reference points done with a rasp and sanding block, took about an hour and was all I had time for yesterday after the fretboard. Knives next on the agenda for the transition to the headstock. I guess the big block sections will get planed and sanded, but I haven’t asked (one step at a time). Obviously the taper and progressively changing radius makes it tricky.

There’s a really great YT channel you may be interested in (guitar repair) called Twoodfrd

While it may be casually rated at 20w it still rips your head off.

Played one at a gig as backline over the weekend. Realistically not much quieter than a 1987x 50w but the tone is to die for

I think doubling watts is equivalent to 3dB increase in sound pressure, so you’re right, not much different between the SV20 and a 1987 in volume. I had a 1W plexi style amp that Marshall used to make, and everyone who heard it was surprised how loud it was.

Yeah, Im lucky to live where I do, so I can play pretty loud and not bother anyone.

If worse comes to worse, I will get an attenuator for it.

I just cant wait to plug a wah, a fuzz and a univibe into it and spray thick wads of scorching fuzz into the ■■■■■■■ cosmos…

Man I love guitars.

It’s great to see you enjoying this process, mate.

Love it, is the highlight of my week ![]()

Love these updates, great workmanship it’s looking gorgeous

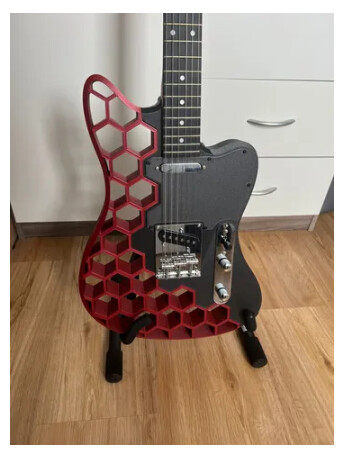

Nice build. I’m about to have a crack at this :

https://www.printables.com/model/398795-the-prusacaster-a-3d-printable-guitar/comments

Interesting! I like the colour of this one.

Is that Bee Bee King’s guitar?

You should have used an emoji to take the potential sting out of that remark

Haha yes I might do one like that. Easy to print the hex parts in different colors. My printer is running 24/7 at the moment as the core takes a long time to print and has a few issues to fit locally available T style kits.